Company:Lanteky mechatronics

Address:No 5558 Chuansha Road, Pudong Discrict, Shanghai, China

Postcode:100102

Email:landy.industry20@gmail.com

-

- Single Axis CNC EDM Machine Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

-

- Three Axis CNC EDM Machine With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component, automation, information and communicat...

-

- CNC EDM Blade Grinder CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

Application 1. EDM machine is mainly used to produce the parts that have the complex shaped hole and cavity.

2. Machining all kinds of hard and brittle materials, such as cemented carbide and chilled hardened steel.

3. Dealing with long-deep holes, irregular holes, deep grooves, narrow slits and slices.

4. Producing many kinds of forming cutters, ring thread gauges and other cutting and measuring tools.

Working Process When machining, the work electrode and the work piece will be connected on the two poles of the pulse source respectively, and soak in the work oil. Through the discharge gap, the auto-control system will control the electrode feed the work piece, when the gap is tiny enough, the impulse voltage will breakdown the work oil in the gap, and cause the electric discharge spark.

The spark will etch the work piece, then the finished work piece which has the same shape corresponding the work electrode will be made/machined. So that the electrical discharge machine can machine different complex molded surfaces through changing the shape of electrode.

Work oil, as the discharge medium, also plays a role in cooling and chip cleaning. Commonly used work oil is the medium that has low viscosity, high flash point, and stable performance. Such as kerosene, deionized water, emulsions and so on.

Related Products

QDY12 Series Servo Valve

QDY12 Series Servo Valve

DLQ6/25 Grease Injection Valve

DLQ6/25 Grease Injection Valve

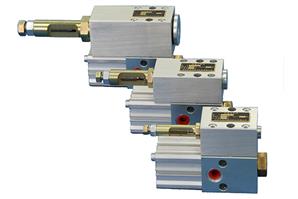

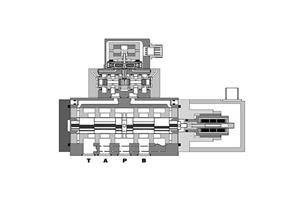

QDY3 Series Servo Valve

QDY3 Series Servo Valve

QDY2 Series Servo Valve

QDY2 Series Servo Valve

SVA-Ⅱ Servo Amplifier

SVA-Ⅱ Servo Amplifier